I’ve been following the $LL saga and have come to a conclusion on but let’s first see how we got here. I’ll put aside Tilson’s thesis on the illegal wood buying (which the Dept of Justice is investigating) and focus on the 60Min piece (any bold type is my doing):

The original piece:

The update, the CPSC has requested the testing data:

Here is how 60 minutes tested the wood:

60 Minutes purchased 31 boxes of Chinese-made laminate flooring from Lumber Liquidators stores in Virginia, Florida, Texas, Illinois and New York and sent them to two certified labs, HPVA and Benchmark International, for two kinds of tests.

First the labs tested the products for CARB (California Air Resources Board) 2 compliance. CARB’s emissions standards regulate the formaldehyde emissions from composite wood products used in finished goods such as laminate flooring. The underlying medium density fiberboard, or “core” of the product must pass CARB’s emissions standards in order for the product to be sold legally in California. CARB publishes its official methodology for analyzing formaldehyde emissions in finished goods – or “SOP” (Standard Operating Procedure for testing finished goods) on its website. 60 Minutes also confirmed with CARB officials that this deconstructive test method is the way they test finished goods for CARB formaldehyde emissions compliance. The labs tested Lumber Liquidators’ Chinese-made laminates, using the method that CARB developed and uses. Thirty of the 31 samples tested contained levels of formaldehyde emissions that exceed the limits set by CARB. It is illegal to sell laminates in California which exceed the formaldehyde emissions limits set by CARB. The labs found that the highest-emitting Lumber Liquidators product tested released 13 times more formaldehyde than the CARB Phase 2 limits.

The second test the labs did was the CDPH (California Department of Public Health test) 01350 test, which measures the concentration of formaldehyde emissions coming off the laminates into the air of a typical home. The highest-emitting Lumber Liquidators sample that the labs tested emitted a concentration of formaldehyde into the air of a typical home that the US EPA (Environmental Protection Agency) has cited as “polluted indoor conditions.”

Here are the full test results

From $LL website:

How is our testing different than 60 Minutes?

60 Minutes used an improper test method in its reporting that is not included in California’s regulations and does not measure a product according to how it is actually used by consumers. 60 Minutes used a “deconstructive test,” which would be like testing the emissions of a car by removing the catalytic converter and muffler. In contrast, we perform California Air Resource Board (CARB) testing on the fiberboard core and A SECOND ROUND OF TESTING on the finished product.Our Emission Results

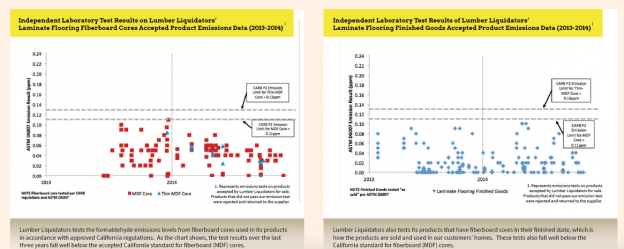

Data includes independent testing of samples from Lumber Liquidators’ suppliers located in China. Click to enlarge.

From the CARB:

CANCER

The International Agency for Research on Cancer (IARC) recently concluded, based on human exposures in the workplace, that formaldehyde can cause nasopharyngeal cancer (cancer of the nose and throat). IARC also found limited evidence that formaldehyde may cause other respiratory tract cancers, and a possible link with leukemia. Previously, the U.S. Environmental Protection Agency had classified formaldehyde as a “probable” human carcinogen, based on studies of laboratory animals repeatedly exposed to high levels of formaldehyde.

When assessing formaldehyde for identification as a California Toxic Air Contaminant, the ARB’s Scientific Review Panel concluded that, like other carcinogens, there is no level of exposure below which the risk of developing cancer is zero. Estimating Californians’ risk from current indoor levels of formaldehyde is complex. As an approximation, if the California population were exposed to current, average indoor levels of formaldehyde over a lifetime, ARB staff estimate that about 4000 excess cases of cancer would be expected to develop, or about 115 excess cases of cancer per million people exposed. Reducing your exposure to formaldehyde will help reduce your individual risk.

What can I do to reduce formaldehyde in my home? There are practical steps you can take to reduce your exposure to formaldehyde in your home. Levels can be reduced whether you are building a new home, remodeling an older home, or seeking to reduce exposure from sources you may have in your home. The most effective way to reduce formaldehyde in indoor air is to remove or reduce sources of formaldehyde in the home and avoid adding new sources.

Formaldehyde from sources such as pressed wood products can take years to off-gas. Additionally, porous materials and furnishings can absorb formaldehyde and re-emit it later. Thus, avoidance of sources and prevention of emissions from the start is best.

So what do we have?

1- $LL does not deny that formaldehyde levels in its wood are too high

2- What they do claim is that 60Min used a faulty testing method (deconstruction)

3- Now, “60 Minutes also confirmed with CARB officials that this deconstructive test method is the way they test finished goods for CARB formaldehyde emissions compliance”

4- Let’s look at it using $LL’s own analogy “60 Minutes used a “deconstructive test,” which would be like testing the emissions of a car by removing the catalytic converter and muffler”

Here is the problem with that analogy. We have to get our cars inspected each year and the moment the muffler or catalytic converter are not filtering out the emissions they should, the car will not pass inspection until they are replaced because it then become dangerous. According to the CAR that $LL directs us to on their site:

Formaldehyde from sources such as pressed wood products can take years to off-gas

So, does this mean that as there is wear and tear on the flooring (this will vary by location) and it begins to break down the currently unacceptably high level of formaldehyde within the wood will then leach into homes? Since there is no testing once they are installed, will no one know? Should we be testing our $LL flooring every year like we do our cars to see just how much is escaping into our home’s air? If we find it is, does CEO Sullivan have a replacement “catalytic converter or muffler” to stop it?

It seems, $LL is arguing form vs substance. They are not saying that the levels are not too high, just that the emissions of them currently aren’t? Isn’t that like saying one cigarette won’t kill you so they are safe?

5- Back to the “deconstruction” issue. According the the CARB itself under “Standard Operating Procedure for Finished Good Test Specimen Preparation Prior to Analysis of Formaldehyde Emissions from Composite Wood Products” :

2. SUMMARY OF METHOD

Finished goods contains pieces of composite wood panels and include such items as cabinets, furniture, flooring, doors, picture frames, and toys. Panels in finished goods often are veneered, laminated, coated, or otherwise manipulated such that the formaldehyde emission characteristics of the original panels may have been changed on one or both sides of the component part. Deconstruction is the process of

separating or cutting the finished good into component parts so that pieces of the underlying panel may be accessed in order to remove the coating or laminate to achieve a test specimen that can be sent to a lab for formaldehyde emissions testing.This process includes removing coatings from hardwood plywood and removing laminates (synthetic or wood veneer) from laminated products to access the underlying composite wood products. For finished goods that consist of a laminated product in which one side is not laminated or coated, the product may be cut and tested as a panel with a surface coating on one side (see SOP for composite wood panels).

The key activity in the deconstruction process is the removal of the surface layer of a specimen using a thickness planer or sander to expose the underlying composite wood panel. This SOP defines how a panel surface is to be removed in order to provide reliable data.The regulation requires a minimum of one specimen to test the formaldehyde emissions of a composite wood product in a finished good. Specimen size is determined by the laboratory to meet the air flow and surface area requirements as defined in the ASTM D6007. Specimen size can vary among laboratories due to differences in equipment, air flow rates, etc. Cut and labeled specimens are stored in resealable bags made of 6- mil plastic or equivalent.

Deconstruction can occur on either one or both sides of the test specimen. If only one side is deconstructed, then two pieces are then placed back to back (deconstructed sides exposed) with the edges taped to make one test specimen. A specimen with both sides deconstructed is also tested with the edges taped and both sides exposed.

So, um…….

6- I’d also be concerned if I was long that this conference call coming up tomorrow to “clear the air” (pun intended) does not seem to have a Q&A session attached to it (I’ve left a message for investor relations but have not heard back). I’m not sure how they can accurately address concerns if they do not take questions.

Further, this is NOT the first time $LL products from China have been found to have failed formaldehyde testing:

Kip Howlett, President of the Hardwood Plywood and Veneer Association in Reston VA said on November 20, 2013:

The Lumber Liquidators flooring which tested as unfinished HWPW failed the CARB emissions standard tested at 0.17 ppm. This proposal would still have it non-compliant even at 0.11 ppm, but did CARB enforce against Lumber Liquidators?

My members have incurred costs to be in compliance which our competitors can avoid. They have and this proposal is an invitation produce and ship higher emitting products. We found and submitted 4 cases of plywood claimed to be PS-2 and CARB certified which failed

the formaldehyde emission standard. To our knowledge no enforcement occurred either by CARB or U.S. Customs. If the current regulation is not enforced, then allowing higher emissions, no testing and no certification makes a mockery of the whole regulatory framework.In the UK Chinese product was mislabeled as coniferous to come in duty free when in fact it was hardwood plywood. The UK’s TTF brought an enforcement action.

So, is all this a moot point? Does CARB have no intention of enforcing their own regulations? How long has $LL liquidators been selling this flooring?

Is the reason CARB is not recommending that residents tear up flooring because they were aware $LL flooring did not pass emissions standards are far back as 2013?

As a general rule, we do not recommend removing a flooring product unless there are noticeable health effects (i.e. nose and throat irritation, a burning sensation of the eyes, wheezing, and difficulty in breathing), and other measures (see below) taken to alleviate them have failed and there is good reason to believe the flooring is the source of the problem.

Imagine the problem if thousands of homeowners (tens of thousands? hundreds of thousands?) began tearing out floors and found that they failed emission standards and that CARB, the body responsible for regulating the flooring knew?